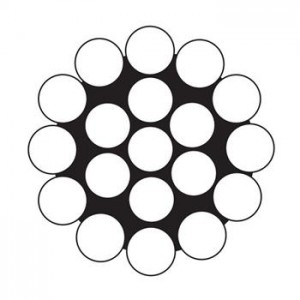

1×19 Galvanized steel wire rope for control cables binding wire

Parameter

| Item | 1*19 Galvanized steel wire rope |

| Material | 45# 55# 60# 70# carbon steel; Inner core: hemp core/PP core/ cotton core |

| Contruction | 1*19 |

| Diameter | 0.8mm, 1mm, 1.2mm, 1.4mm, 1.5mm, 1.8mm, 2mm, 2.5mm,3mm, 3.5mm, 4mm,5 mm, 6mm, 7mm, 8mm |

| Surface treatment | Hot-Dip galvanized/ electric galvanized |

| Package | Packing in coil, wooden reel, plastic reel; Or cut into customized length; Other customized package |

| Application | Good softness, suitable for traction, pulling, strapping, etc. |

Product Description

1×19 steel wire rope is a single-strand steel wire rope composed of 19 steel wires.

It is widely used in small size steel wire ropes, such as planting drawing wire,

inner wire of control cable and brake cable of automobile and motorcycle,

inner wire of plastic-coated steel wire skipping rope, etc.

It is often used to replace 7*7 wire rope in same diameter because of its low price.

Difference between Electric gslvanized and Hot-dip galvanized

The commonly used steel wire rope galvanizing process is hot-dip galvanizing and electro-galvanizing.

Hot-dip galvanized steel wire rope:

Hot-dip galvanizing is also called hot-dip galvanizing and hot-dip galvanizing. It is an effective method of metal anticorrosion.

It is to immerse the derusted steel wire in a molten zinc solution at about 500℃ to make the surface of the steel wire adhere to a zinc layer,

thereby achieving The purpose of anti-corrosion. Hot-dip galvanizing has good coverage ability, the obtained coating is thicker, and the coating is dense.

After a long time of use, even if it is damaged by oxidation, it will continue to form a protective film to continuously protect the inside.Hot-dip galvanizing is made of older hot-dip galvanizing. Method developed.

Electro-galvanized steel wire rope:

Electroplating is the process of using electrolysis to attach a metal film to the surface of metal or other materials,

so as to prevent the oxidation and corrosion of the steel wire rope, and can improve the wear resistance, conductivity,

light reflection, and corrosion resistance of copper sulfate. And to enhance the beauty and other functions.

The electro-galvanized layer is thin, mainly to enhance the corrosion resistance of the wire rope, increase the hardness,

prevent abrasion, improve the conductivity, smoothness, heat resistance and beautiful surface.

The main difference between the two is:

Simply put, the production process of hot-dip galvanized steel wire rope is complicated, the zinc layer is evenly distributed,

the amount of zinc applied is higher, and the resulting coating is thicker.

Hot-dip galvanizing has better protection performance than electro-galvanized steel wire rope, so as to achieve a longer service life.

Therefore, it is an important protective coating for steel parts used in harsh working environments, and it is widely used.

Application

Packing & Delivery

PACKING

(1) steel wire ropes will be wrapped in wooden reel or plastic reel, then with plastic film

(2) put on pallets or in wooden case.

(3) packing as your requirements.

DELIVERY

We support international express for your sample order: Like TNT, DHL, FedEx, UPS, EMS, etc.

We shipping the bulk order by Sea, by train, etc.

Produce time: 7-15 working days

Related Products

Our Service

1. As a manufacturer, we are a company integrating factory production with trade and sales.

2. We have a history of more than ten years. In addition, we have a mature sales system, which can provide professional services to our customers.

3. Our company has passed ISO ,CE, SGS .

4. We can design and manufacture products according to the required size and specifications according to the needs of different customers.

5. We accept custom logo printing.

Factory Show

Related PRODUCTS

-

E-mail

-

Phone

-

Whatsapp

whatsapp

-

Wechat

Wechat

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu